Introduction

In the dynamic and often hazardous world of industrial operations, ensuring safety and maintaining efficiency are critical priorities. At the heart of this commitment lies the ACTT Service Program SP 3-872-009 Shut Down Harness. More than just a connector, this harness is an essential safety device that provides a crucial safety link between machinery and emergency shutdown systems, making it a vital component in preventing accidents and enhancing operational reliability. This guide explores the ACTT Service Program SP 3-872-009 Shut Down Harness, its features, significance, installation, maintenance, and practical applications.

Table of Contents

What does the ACTT Service Program SP 3-872-009 Shutdown Harness entail?

The ACTT Service Program SP 3-872-009 Shut Down Harness is specifically engineered to facilitate swift and safe shutdowns of equipment during emergencies or maintenance operations. It acts as a reliable safety mechanism that interrupts operations when needed, which is particularly critical in high-risk environments where equipment failures could lead to severe injuries or damage to property. This harness is designed to integrate seamlessly into various machinery setups across different industries, ensuring robust performance even in harsh conditions.

Key Features of the ACTT Service Program SP 3-872-009 Shut Down Harness

Durable Construction

Manufactured with high-quality materials, the ACTT Service Program SP 3-872-009 Shut Down Harness is built to withstand the rigorous demands of industrial environments. Its robust construction ensures longevity and consistent performance, even under exposure to harsh elements and heavy use.

User-Friendly Design

One of the standout features of this harness is its user-friendly installation process. Designed for easy integration, it minimizes downtime during setup, ensuring that equipment can be operational quickly and efficiently. This straightforward installation process saves valuable time and reduces potential disruption to ongoing operations.

Wide Compatibility

The ACTT Service Program SP 3-872-009 Shut Down Harness offers versatility, making it compatible with a wide range of machinery across different industries. From manufacturing plants to construction sites, its adaptability allows for seamless integration into existing safety systems, providing enhanced safety measures without extensive modifications.

Compliance with Safety Standards

Adherence to stringent industry safety standards is a key feature of the ACTT Service Program SP 3-872-009 Shut Down Harness. This compliance ensures that the harness performs reliably under the most demanding conditions, offering peace of mind to both operators and management by meeting critical safety requirements.

Enhanced Signal Clarity

Designed to provide clear signals during operations, the ACTT Service Program SP 3-872-009 Shut Down Harness ensures prompt activation of the shutdown mechanism. This enhanced signal clarity is crucial for preventing accidents and minimizing potential risks, contributing to a safer working environment.

The Significance of the ACTT Service Program SP 3-872-009 Shut Down Harness

The ACTT Service Program SP 3-872-009 Shut Down Harness is crucial for maintaining safety, minimizing downtime, and improving operational efficiency in industrial environments.

Here’s why it’s an indispensable component:

Prevention of Accidents

Safety is paramount in any industrial setting. The ACTT Service Program SP 3-872-009 Shut Down Harness is crucial for accident prevention, offering a quick and reliable means to shut down machinery in case of malfunctions. This capability significantly reduces the risk of serious injuries or fatalities, protecting workers and assets alike.

Minimizing Downtime

Equipment failures and accidents can lead to costly downtime. The ACTT Service Program SP 3-872-009 Shut Down Harness allows for rapid shutdowns, minimizing the extent of damage and enabling quicker recovery. This efficiency helps maintain productivity and reduces financial losses for businesses.

Enhancing Worker Confidence

Workers feel safer and more secure when they know they are protected by reliable safety equipment like the ACTT Service Program SP 3-872-009 Shut Down Harness. This confidence can lead to improved focus and productivity, benefiting the overall operation of the business.

Cost-Effectiveness

Prioritizing safety equipment proves to be a worthwhile investment over time. The ACTT Service Program SP 3-872-009 Shut Down Harness reduces the costs associated with accidents and equipment failures by preventing accidents and minimizing downtime, ultimately saving money on repairs, replacements, and lost productivity.

Compliance with Regulations

Many industries are subject to stringent safety regulations. The ACTT Service Program SP 3-872-009 Shut Down Harness helps businesses comply with these regulations, avoiding fines and legal issues that can arise from non-compliance.

Installation Process of the ACTT Service Program SP 3-872-009 Shut Down Harness: Guaranteeing Safety and Optimal Performance

Proper installation is crucial for the optimal performance of the ACTT Service Program SP 3-872-009 Shut Down Harness.Follow these comprehensive steps to guarantee a smooth setup process:

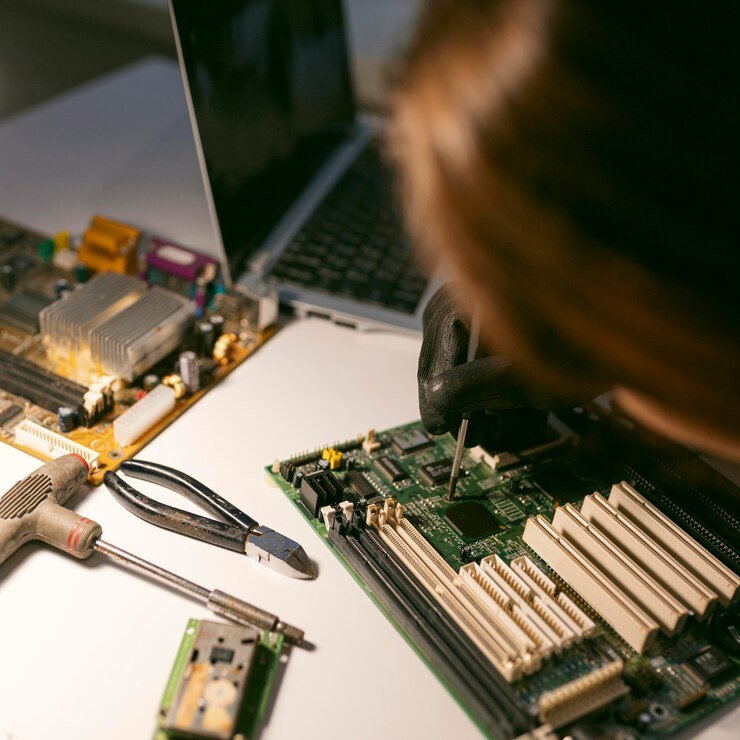

Step 1: Gather Necessary Tools Before starting the installation, gather all required tools to ensure the process goes smoothly:

Screwdrivers (both flathead and Phillips)

Wire cutters

A multimeter for testing connections

Wear safety gloves and goggles to ensure personal protection during the installation process.

Power Down the Equipment Safety is always the top priority. Before beginning the installation, power down the equipment and disconnect it from the main power source to prevent any potential electrical hazards during the process.

Remove the Old Harness If you’re replacing an existing harness, carefully disconnect the wiring and remove the old harness. Take note of the connections and document them for reference during the installation of the new harness. It may also be helpful to take photos for later use.

Connect the New Harness Carefully attach the ACTT Service Program SP 3-872-009 Shut Down Harness according to the manufacturer’s instructions. Make sure all connections are tight and well-insulated to prevent electrical short circuits.

Test the System After the new harness is installed, reconnect the power and perform a thorough system test. Verify that the shutdown mechanism activates as intended. This step is critical to ensure the harness operates correctly during emergencies.

Monitor Regularly Once the installation is complete, establish a routine for monitoring the harness and its connections. Regular inspections will help identify any signs of wear or potential issues before they escalate, ensuring long-term safety and reliability.

Maintenance Tips for the ACTT Service Program SP 3-872-009 Shut Down Harness

To maintain the ACTT Service Program SP 3-872-009 Shut Down Harness in optimal condition, regular maintenance is essential. Here’s how to keep it functioning reliably:

Routine Inspections Conduct regular inspections of the harness to check for any signs of wear, fraying, or corrosion. Inspect the connections and wiring for any damage that could impact performance.

Keep Connections Clean Dirt, debris, and corrosion can impede the effectiveness of the harness. Regularly clean all connections to maintain a reliable signal.

Always follow the maintenance guidelines provided by the manufacturer. These guidelines are specifically designed to ensure the longevity and reliability of the harness.

Replace When Necessary If you notice significant wear, damage, or performance issues, replace the harness immediately. Safety and reliability should be the foremost priorities.

Document Maintenance Activities Keep a log of maintenance activities, including inspections, repairs, and replacements. This documentation is invaluable for tracking the history of the harness and ensuring compliance with safety regulations.

Real-World Applications of the ACTT Service Program SP 3-872-009 Shut Down Harness

The ACTT Service Program SP 3-872-009 Shut Down Harness is widely used across various industries, enhancing safety and efficiency. Here are some real-world applications:

Manufacturing In manufacturing facilities, the ACTT Service Program SP 3-872-009 Shut Down Harness is commonly used with heavy machinery to quickly and safely shut down equipment during malfunctions, protecting workers and preventing costly equipment damage.

Construction Construction sites often involve high-risk activities with heavy machinery. The harness is used to manage cranes, excavators, and other equipment, ensuring that operators can safely shut down machines in emergencies.

Mining In the mining industry, safety is critical due to hazardous conditions. The harness integrates into mining equipment to provide a reliable shutdown capability, protecting workers from potential accidents.

Agriculture Agricultural equipment, such as tractors and harvesters, can also benefit from the ACTT Service Program SP 3-872-009 Shut Down Harness. It ensures safety during operations in the field by allowing for immediate shutdown capabilities.

Oil and Gas In the oil and gas sector, safety is paramount due to the dangerous nature of the work. The harness is used across various applications, from drilling rigs to processing plants, ensuring that equipment can be safely shut down when needed.

Common Issues and Troubleshooting Tips

While the ACTT Service Program SP 3-872-009 Shut Down Harness is designed for reliability, some common issues may occur. Here’s how to troubleshoot them:

Failure to Activate Issue: The shutdown mechanism does not activate when triggered. Solution: Ensure all connections are secure and intact. Inspect the wiring for any signs of damage or wear. Use a multimeter to check the continuity of the harness.

Intermittent Functionality Issue: The harness works sporadically. Solution: This could be due to loose connections or frayed wiring. Thoroughly inspect the harness and tighten any loose connections. Replace damaged sections if necessary.

Unresponsive System Issue: The entire system becomes unresponsive when attempting to use the harness. Solution: Ensure that the main power supply is connected and functioning. Check for blown fuses or tripped circuit breakers that might be affecting the system.

Corrosion Issue: Corrosion on connectors affecting performance. Solution: Clean the affected areas using a suitable corrosion remover. Apply dielectric grease to protect connections from future corrosion.

Aging Components Issue: Over time, components may degrade, impacting reliability. Solution: Replace aging harnesses as part of a proactive maintenance strategy. Regularly assess the age and condition of all components.

Conclusion

The ACTT Service Program SP 3-872-009 Shut Down Harness is an essential safety device in industrial settings, providing reliable and efficient means to manage equipment shutdowns during emergencies. Its robust construction, user-friendly design, and compliance with stringent safety standards make it a valuable asset for preventing accidents, reducing downtime, and enhancing worker confidence. Regular maintenance and proper installation are crucial to ensure its continued functionality and longevity. By integrating this harness into various industrial operations, businesses can safeguard their workforce, minimize operational disruptions, and comply with industry regulations.

FAQs

What does the ACTT Service Program SP 3-872-009 Shut Down Harness involve?

The ACTT Service Program SP 3-872-009 Shut Down Harness is a specialized safety device designed to facilitate swift and safe shutdowns of equipment during emergencies or maintenance operations in industrial settings. It acts as a reliable safety mechanism, ensuring protection against accidents and equipment failures.

What are the Notable Characteristics of the ACTT Service Program SP 3-872-009 Shut Down Harness?

The key features include durable construction, user-friendly installation, wide compatibility with various machinery setups, compliance with safety standards, and enhanced signal clarity for prompt activation during emergencies.

Why is the ACTT Service Program SP 3-872-009 Shut Down Harness important in industrial settings?

The harness is crucial for preventing accidents, minimizing downtime, enhancing worker confidence, and ensuring compliance with industry regulations. It provides a quick and reliable way to shut down machinery, protecting both workers and equipment from potential hazards.

How should the ACTT Service Program SP 3-872-009 Shut Down Harness be installed? Installation involves powering down the equipment, removing the old harness, connecting the new harness according to the manufacturer’s instructions, testing the system, and regularly monitoring the connections and components to ensure long-term safety and reliability.

What maintenance is required for the ACTT Service Program SP 3-872-009 Shut Down Harness?

Regular inspections for wear and damage, cleaning connections, following the manufacturer’s guidelines, and replacing components when necessary are key maintenance activities to ensure the harness remains functional and reliable. Documenting maintenance activities is also crucial for compliance and tracking the history of the harness.

For any kind of updates please visit Mywape